Which of the Following is Recommended Maintenance for an Inboard Boat? Essential Tips for Optimal Performance

Regular maintenance for an inboard boat is crucial for keeping it in good shape and ensuring safe outings on the water.

Essential maintenance tasks include changing the engine oil, inspecting the propeller, and checking the cooling system. These steps can help your boat run smoothly and avoid major repairs.

Routine inspections also involve the fuel system, including replacing the fuel filter and ensuring there are no leaks.

Proper battery care is another vital part, as a reliable power source can prevent unexpected breakdowns.

Don't forget to clean the hull and lubricate the steering system to enhance the boat's performance.

In the colder months, boaters should prepare for winter by draining water from the engine, adding antifreeze, and checking the trailer tires. These measures protect the boat during storage and make it ready for action when spring arrives.

Key Takeaways

- Regular engine checks and oil changes are essential.

- Maintain the fuel and electrical systems for reliable performance.

- Proper winterization and storage protect the boat off-season.

Understanding Inboard Boats

Inboard boats have their engines mounted inside the hull, which is different from outboard boats that have engines attached externally.

These boats are popular for their high performance and power.

Inboard engines generally allow for better weight distribution. This feature can improve the boat's handling and overall stability in the water. Many larger and more powerful boats use inboard engines.

Regular maintenance keeps inboard boats in good condition. Important tasks include changing engine oil, replacing zincs, and inspecting components like the steering cables.

These boats come in various sizes and designs, catering to different needs. Smaller inboard boats might be used for watersports, while larger ones are often preferred for cruising.

Ventilation systems are crucial for safety, especially in inboard gasoline boats. Ensuring proper ventilation minimizes risks associated with gasoline fumes.

Regular Maintenance Routines

To keep an inboard boat running smoothly, routine maintenance is essential. Key activities include engine checks, oil and filter changes, and cooling system maintenance.

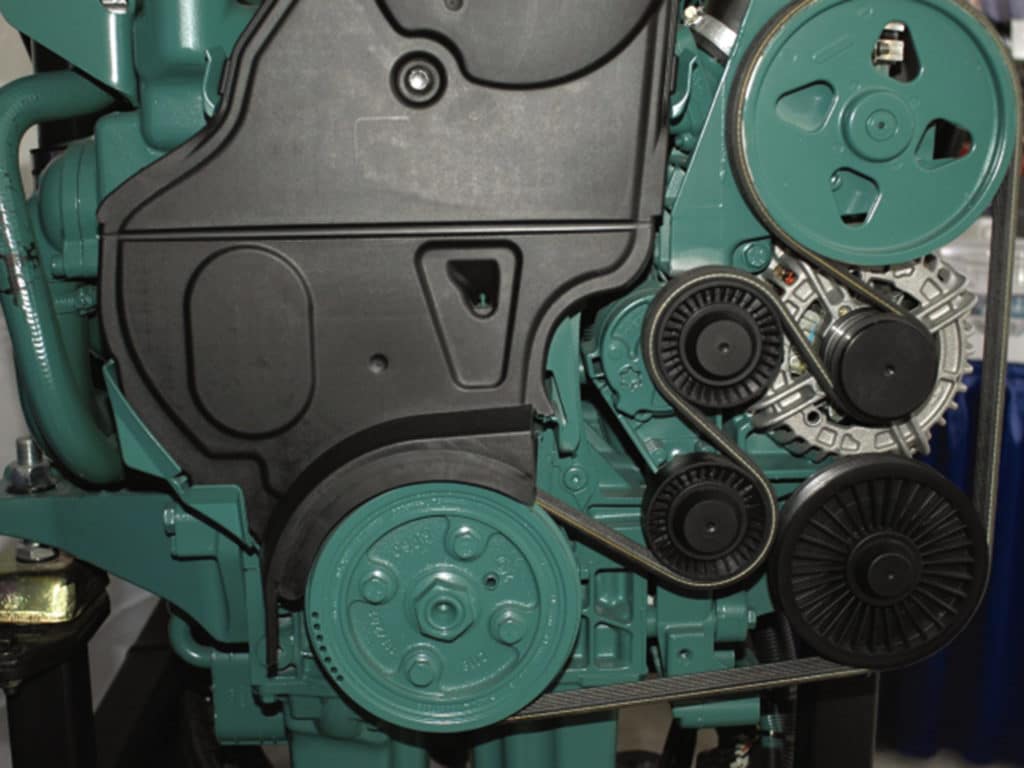

Engine Checks

Regular engine checks help identify potential problems early.

It's important to inspect the motor for any signs of wear or damage. Look for leaks or corrosion around the engine area.

Testing the performance of the engine can prevent costly repairs.

Check belts and hoses to ensure they are not cracked or frayed. Also, inspect the spark plugs and replace them if they show signs of wear.

Keeping the motor clean and free of debris is crucial.

Checking fluid levels, including coolant and steering fluid, is also recommended.

Oil and Filter Changes

Changing the oil and oil filter is critical to maintaining engine performance.

Fresh oil lubricates the internal components, reducing friction and heat buildup.

It’s important to replace the oil filter during this process, as it removes contaminants from the oil.

An oil replacement should follow the manufacturer's recommendations, typically every 100 hours of operation or annually.

To perform an oil change:

- Warm up the engine.

- Drain the old oil.

- Replace the oil filter.

- Add new oil.

Properly disposing of the old oil and filter is also important to protect the environment.

Cooling System Maintenance

The cooling system prevents the engine from overheating.

Regular flushing of the engine with fresh water removes salt and mineral deposits. This helps avoid corrosion and maintain performance.

- To maintain the cooling system:

- Check coolant levels regularly.

- Add antifreeze as needed, especially before winter storage.

- Inspect hoses and connections for leaks or damage.

Keeping the cooling system in good working order extends the life of the motor and helps prevent costly breakdowns.

Flushing the engine after each use, especially in saltwater environments, is highly recommended.

Hull & Propeller Care

Taking care of your boat's hull and propeller is essential for maintaining performance and safety. This involves regular inspections, cleaning, and timely replacements to prevent issues like corrosion and marine growth.

Inspecting and Cleaning the Hull

Regular hull inspections help identify damage, such as cracks or scratches.

Visually inspect the hull for minor dents and deeper damage. Early detection can prevent bigger problems later.

Marine growth on the hull slows down the boat and affects performance.

Cleaning the hull removes this growth, ensuring smooth operation. Use a soft brush and marine-friendly cleaner for best results.

Hull zinc anodes prevent corrosion by sacrificing themselves.

Check these anodes regularly. Replace them when they are more than half-worn. This simple step protects against severe corrosion.

Maintaining and Replacing Propellers

A well-maintained propeller is crucial for a boat's efficiency.

Inspect propellers for dents, cracks, and corrosion. Any damage can reduce performance and could lead to engine strain.

Remove marine growth from the propeller regularly. Clean it thoroughly for smooth rotation.

A plastic scraper can help remove any build-up without damaging the material.

Checking propeller balance is also important. An unbalanced propeller causes vibrations, which affect the boat’s performance.

Replace damaged or corroded propellers promptly to avoid these issues.

Electrical System Upkeep

Regular maintenance of the electrical system is essential for an inboard boat.

Battery Care: Ensure batteries are properly charged and clean. Remove any corrosion from terminals using a mixture of baking soda and water. Check connections for tightness and replace damaged cables.

Wiring Inspection: Look for signs of wear or damage on the electrical wiring.

Insulating worn-out wires can prevent shorts and fires. Replace any frayed or broken wires immediately.

Fuses and Circuit Breakers: Test and replace any blown fuses or tripped breakers. A properly functioning fuse box maintains consistent electrical performance.

Lighting: Verify that all navigation and interior lights operate correctly. Replace burnt-out bulbs and inspect fixtures for corrosion or damage.

Regular checks help detect issues early and keep the boat's electrical system running smoothly. This ensures a safer and more enjoyable boating experience.

Fuel System Care

Regular maintenance of the fuel system is vital for an inboard boat.

Checking and Replacing Fuel Filters: Fuel filters should be checked and replaced regularly.

Clean filters prevent dirt, water, and debris from entering the engine, which can cause damage and reduce fuel efficiency.

Fuel Stabilizer Use: Adding a fuel stabilizer can help prevent gasoline breakdown and oxidation.

This is crucial, especially if the boat will be idle for long periods. Fuel stabilizers also prevent issues related to ethanol-blended gasoline.

Inspect for Corrosion: Regular inspection for signs of corrosion in the fuel system is essential.

Corrosion can lead to leaks and more severe damage if not addressed promptly.

Replace Worn Parts: Any worn or damaged parts in the fuel system should be replaced immediately. This includes hoses, clamps, and any other components showing signs of wear.

Winterization and Storage

Proper winterization and storage of an inboard boat are crucial for preventing damage and ensuring it is ready for the next season. This involves preparing the boat for cold weather and finding the right storage solution to protect it from the elements.

Preparing for Winter

Winterizing an inboard boat starts with changing the oil and oil filters to prevent corrosion.

The engine should be flushed with fresh water to remove any salt or debris.

Antifreeze should be circulated through the engine and manifolds following the owner's manual instructions.

Next, drain all onboard freshwater tanks and open water outlets until water stops sputtering.

Then, add nontoxic propylene glycol antifreeze to the tanks to prevent freezing.

Make sure that the antifreeze has run through all the plumbing, including heads and holding tanks.

Cleaning the boat thoroughly, both inside and out, is also important. Remove any organic material to prevent mold and mildew.

Covering the boat with a protective cover will shield it from environmental damage and keep it dry.

Storage Solutions

Finding the right storage solution is key to maintaining an inboard boat during winter. Options include indoor storage, outdoor storage, and dry stack storage.

Indoor storage offers the best protection against weather and potential damage. It keeps the boat out of direct sunlight which can cause fading and other wear.

Outdoor storage is a more economical option but requires a heavy-duty cover to protect against snow and ice.

Dry stack storage involves stacking boats in a covered or uncovered racking system. This method prevents water accumulation around the hull but does not offer the same level of protection as indoor storage.

Each storage option requires the boat to be properly winterized to prevent cold weather-related issues.

Avoiding Common Repair Issues

Regular maintenance helps to avoid many common repair issues for inboard boats. Here are some key steps:

Check for Corrosion:

Boat parts, especially engine and hull zincs, can corrode.

Replace deteriorated zincs to prevent damage.

Inspect Thru-Hull Fittings:

Leakage or corrosion in these fittings can lead to costly repairs. Regular inspection is crucial.

Exhaust Blower Operation:

Before starting an inboard gasoline engine, always operate the exhaust blower. This clears gasoline vapors and prevents possible engine damage.

Battery Maintenance:

Replace batteries every 2-5 years or when voltage drops below 11.8 watts. Low voltage levels can cause engine starting problems.

Key Items to Monitor:

| Maintenance Task | Frequency |

|---|---|

| Replace hull zincs | When corroded |

| Inspect thru-hull fittings | Regularly |

| Operate exhaust blower | Before each start |

| Check battery voltage | Annually or as needed |

Proper maintenance reduces the risk of unexpected repairs and ensures a smooth and safe boating experience.

Maximizing Boat Performance

Regular maintenance is key to maximizing the performance of an inboard boat.

Engine and hull zincs need to be checked and replaced if corroded. Corroded zincs can lead to serious damage, affecting performance.

Batteries should be monitored closely. They typically need to be replaced every 2-5 years. The voltage level must be checked regularly, and batteries should be replaced when their voltage drops to 11.8 watts.

Thru-hull fittings must be examined for any signs of leakage or corrosion. Any issues here can cause water to enter the boat, which can severely impact performance and safety.

Routine inspection and cleaning of the propeller are also important. Make sure there are no dings or bends. A damaged propeller can reduce efficiency and cause vibrations, affecting overall performance.

Another key task is to check and maintain the fuel system.

Replace old or damaged fuel lines and ensure that filters are clean and free of debris.

For the best performance, the engine should receive a comprehensive check annually. This includes oil changes, filter replacements, and a thorough check of cooling systems.

Budgeting for Maintenance

Maintaining an inboard boat can be expensive, but careful budgeting can help manage costs.

It is wise to plan for both regular maintenance and unexpected repairs.

Annual service work might include engine checks, fluid level inspections, and battery replacements. These routine tasks are essential for keeping the boat running smoothly.

| Service Type | Cost Range |

|---|---|

| Skilled work (engine, electrical) | $70 - $140 per hour |

| Unskilled projects (cleaning, waxing) | $40 - $80 per hour |

Investing in regular upkeep can prevent more costly repairs.

For example, replacing deteriorated engine and hull zincs can protect against corrosion and save money in the long run.

Lubricating the steering components and checking thru-hull fittings for leaks are vital tasks that ensure safety and enhance the boat's lifespan.

They should consider the value of their boat and budget accordingly to maintain its worth. Neglecting maintenance can lead to significant devaluation.

Key Maintenance Tasks:

- Engine oil and fluid level checks

- Battery voltage inspections

- Greasing steering cables

- Replacing corroded parts

Frequently Asked Questions

Maintenance for an inboard boat involves routine tasks to ensure safe and efficient operation. The following FAQs address common concerns related to safety and maintenance practices for inboard boats.

What should you do if caught in severe storm conditions while boating?

If caught in severe storm conditions, the boat operator should first ensure all passengers are wearing life jackets.

The boat should be headed into the waves at a 45-degree angle.

Reducing speed is also crucial to maintain control and minimize the impact of the waves.

Which tasks are included in the annual maintenance program for a gasoline-powered inboard boat?

Annual maintenance for a gasoline-powered inboard boat includes checking and replacing deteriorated engine and hull zincs if they are corroded.

The voltage level of the battery should also be checked, and the battery replaced if necessary.

Ensuring the exhaust blower operates correctly and lubricating necessary parts are additional tasks.

When you see a thunderstorm approaching while boating, what is the best course of action to take?

When a thunderstorm is approaching, the best course of action is to head to the nearest shore immediately.

Dark clouds and sudden temperature drops are signs of an approaching storm and should not be ignored.

Ensure all safety equipment is accessible and passengers are wearing life jackets.

What safety precautions should be prioritized by a boat operator when navigating in stormy weather?

In stormy weather, a boat operator should prioritize ensuring that all passengers have life jackets on and securing loose items onboard.

They should operate at a reduced speed and keep an eye out for floating debris.

Continuous monitoring of weather updates is also essential for safety.

What procedures should be avoided when retrieving a boat at a ramp?

When retrieving a boat at a ramp, avoid blocking the ramp for extended periods.

Do not leave the boat unattended while it is still in the water.

Avoid excessive speed when approaching the ramp to prevent accidents.

Ensuring the boat is properly secured before transporting it is also crucial.

After retrieving a boat onto a trailer, what is the first action you should take?

After retrieving a boat onto a trailer, the first action is to secure the boat with straps, ensuring it is stable on the trailer.

Next, check that the trailer is hitched properly to the towing vehicle and all lights and signals are functioning correctly before driving away from the ramp.

Charlie is Editor-in-Chief of Sea Magazine