Sonihull vs Hullshield: Comparing Top Ultrasonic Anti-Fouling Systems

Ultrasonic anti-fouling systems have become increasingly popular among boat owners looking to protect their vessels from problematic marine growth. Two leading brands in the market, Sinohull and Hullshield, offer advanced solutions that cater to various needs and requirements of yacht and boat enthusiasts. Comparing these systems is essential to determine which one best suits individual preferences and offers the most effective protection.

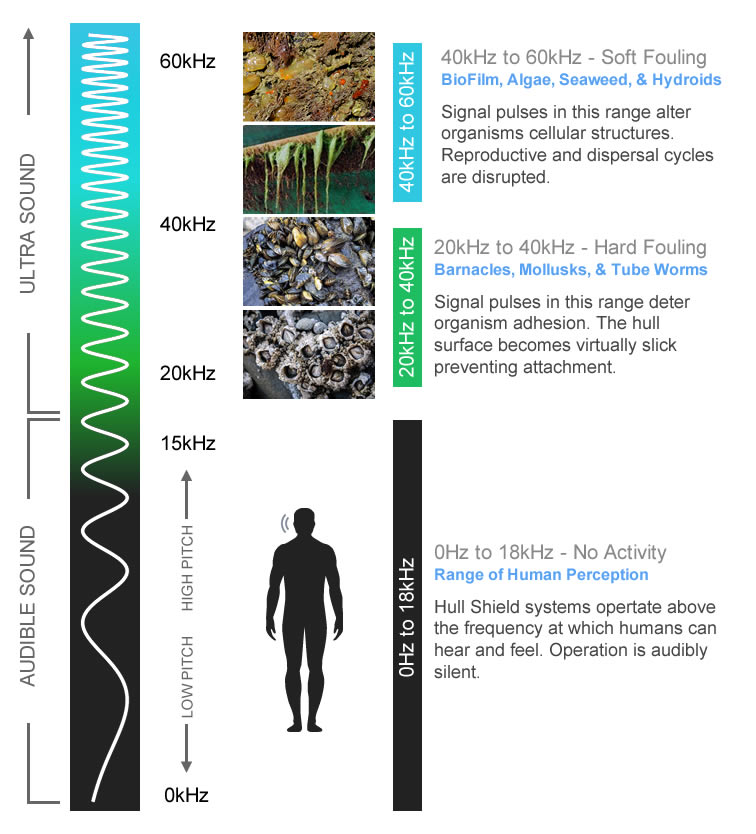

Sinohull and Hullshield both use ultrasonic antifouling technology to deter the accumulation of algae, barnacles, and other marine growth on the hulls of boats and yachts. These systems utilize digital electronics and ultrasonic transducer technology to generate high-frequency sound waves that create an inhospitable environment for marine organisms. As a result, boat owners can experience increased fuel efficiency, reduced maintenance costs, and improved overall performance of their vessels.

While both brands promise excellent performance, there are subtle differences in their features, ease of installation, and pricing that might influence a boat owner's decision when choosing between Sinohull and Hullshield. This article aims to provide a thorough comparison, outlining the strengths and weaknesses of each system, and ultimately helping potential buyers make an informed choice for their boats' ultrasonic antifouling needs.

Overview of Sinohull and Hullshield Systems

Sinohull Ultrasonic Anti-Fouling System

The Sinohull Ultrasonic Anti-fouling System is designed as a "Fit & Forget" solution aimed at preventing marine organisms from colonizing solid surfaces exposed to raw seawater. Suitable for application on hulls, marine structures, box coolers, sea chests, and strainers, this system is designed to be an eco-friendly approach to minimize bio-fouling. By using ultrasonic technology, the Sinohull system aims to prevent biological growth on surfaces without harming the marine life or using harmful chemicals.

Key features of the Sinohull Ultrasonic Anti-fouling System include:

- Effective and eco-friendly antifouling method

- Can be applied to various marine surfaces

- Reduces the need for frequent hull cleaning

Hullshield Ultrasonic Anti-Fouling System

On the other hand, the Hull Shield Ultrasonic Anti-Fouling System is also engineered to use ultrasonic anti-fouling technology. This system has been adopted by the US Coast Guard, Navy, and commercial shipping vessels. Hull Shield is promoted as a cost-effective solution to prevent bio-fouling from attaching to boat hulls and other marine surfaces.

The Hull Shield System offers different configurations, such as the HD100 system that comes with four transducers and the low-cost HD1 system with a single transducer. These systems can be installed within a single day using basic tools, making it a convenient solution for boat owners.

Some of the advantages of the Hullshield Ultrasonic Anti-Fouling System are:

- Based on technology used by the US Coast Guard, Navy, and commercial vessels

- Offers various configurations for different marine applications

- Quick and easy installation

Comparison of Performance

Efficiency and Effectiveness

When comparing the performance of ultrasonic antifouling systems, efficiency and effectiveness are essential factors to consider. Sonihull is known for its use of sound to clean hulls, which can double the life span of anti-fouling paint and reduce planned haul-outs by half. As for Hull Shield, it boasts a single transducer and controller that offer efficient and powerful ultrasonic antifouling.

Power Consumption

In terms of power consumption, both Sonihull and Hull Shield take pride in their energy efficiency. While specific power consumption values for these products may vary, their primary objective is to provide an environmentally friendly and cost-effective solution to bio-fouling and marine fouling.

Coverage and Protection

Coverage and protection play a significant role in the performance of ultrasonic anti-fouling systems. The Hull Shield HD1 can be used independently or combined with other devices for extended protection. On the other hand, Sonihull's coverage is based on factors such as fouling habitat, vessel material, and the surface being protected. Both systems aim to provide adequate and comprehensive anti-fouling coverage.

Impact on Marine Life

Taking into account the impact on marine life, Sonihull and Hull Shield strive to be environmentally friendly alternatives to traditional anti-fouling methods. Ultrasonic systems like Sonihull and Hull Shield don't rely on harmful chemicals, which means they cause minimal disturbance to marine life and surrounding ecosystems. Additionally, these systems contribute to fuel efficiency, as they help maintain streamlined hulls for better maneuverability and reduced engine wear and tear.

Installation and Maintenance

Installation Procedure and Requirements

Both Sonihull and HullShield ultrasonic anti-fouling systems have straightforward installation processes, catering to different requirements and preferences. To install a Sonihull system, begin by sanding the hull surface smooth and flat to ensure the best surface-to-surface transmission of the transducer pulse. Apply petroleum jelly to the threads, apply epoxy to the face of the mounting ring, and attach it to the hull. Allow the epoxy to fully set before attaching the transducer source.

On the other hand, the HullShield system offers flexible installation options, with varying transducer configurations depending on the desired coverage area. The HullShield HD100, for instance, is a four-transducer system ideal for extended protection source. Ensure your chosen transducer arrangement is compatible with your boat's hull and components.

Maintenance and Cleaning

Regarding maintenance, ultrasonic anti-fouling systems like Sonihull and HullShield significantly reduce the need for frequent hull cleaning. For instance, installing an ultrasonic antifouling system on a boat dramatically decreases the necessity to lift and scrub the fouled hull, reducing overall maintenance source.

HullShield systems, when used alongside soft ablative bottom paint, require less maintenance and cleaning compared to boats without bottom paint. Although boats using HullShield without bottom paint still benefit from extended periods between cleaning, removing fouling may be more difficult source.

It's essential to regularly inspect your ultrasonic anti-fouling system to ensure it is functioning correctly and keeping your hull and running gear clean. This inspection will help minimize downtime and maximize your boat's performance.

In summary, both Sonihull and HullShield systems provide accessible installation and significantly reduce hull maintenance and cleaning. While each system has unique installation requirements and procedures, their benefits in minimizing fouling and extending time between cleanings are apparent. Ultimately, the choice between systems will depend on your specific boat, budget, and preferences.

Design and Materials

Transducers and Controllers

Sonihull's ultrasonic anti-fouling systems utilize advanced digital electronics and ultrasonic transducer technology for efficient bio-fouling prevention. These transducers are designed to offer environmentally friendly and effective protection against marine growth without the use of toxic biocides or microplastics, making them a popular choice for modern vessel owners 1.

On the other hand, Hull Shield's HD100 system boasts a four-transducer design, engineered to provide powerful ultrasonic antifouling performance. This system can be used independently or combined with other systems for extended protection 2. Both Sonihull and Hull Shield's controllers are designed to be easy to install and maintain, without the need for dry docking or expensive impressed current antifouling copper anodes replacement 3.

Compatibility with Vessels

Sonihull's ultrasonic antifouling systems are compatible with various vessel types, including those made of wood, steel, GRP (glass-reinforced plastic), aluminum, and Kevlar 4. They provide a fit-and-forget solution for hulls, marine structures, box coolers, sea chests, and strainers, effectively preventing marine organisms from colonizing solid surfaces exposed to raw seawater 5.

Similarly, Hull Shield systems offer versatility and adaptability to various marine vessels. The HD100 system can be used not only for hulls but also for drives, rudders, stabilizers, and other components that might be susceptible to fouling. Like Sonihull, these systems are compatible with boats constructed from different materials such as wood, steel, GRP, aluminum, and Kevlar 6.

In conclusion, both Sonihull and Hull Shield's ultrasonic antifouling systems provide effective and environmentally friendly options for vessel protection. Their compatibility with various boat materials and components make them an ideal choice for boat owners seeking efficient and eco-friendly antifouling solutions.

Footnotes

- https://sonihull.com/ ↩

- https://www.hullshield.net/ ↩

- https://sonihull.com/ultrasonic-antifouling ↩

- https://sonihull.com/ultrasonic-antifouling ↩

- https://sonihull.com/ultrasonic-antifouling ↩

- https://www.hullshield.net/product/hull-shield-hd100-ultrasonic-antifouling-system/ ↩

Additional Features and Applications

Prevention of Biofouling and Corrosion

Ultrasonic anti-fouling systems like Sonihull and Hull Shield are designed to prevent biofouling and corrosion on various surfaces exposed to seawater. These systems utilize ultrasonic transducer technology, emitting sound waves that create a micro-oscillation on the surface, thus inhibiting the growth of marine organisms such as algae and barnacles without the use of toxic chemicals.

Sonihull and Hull Shield both offer protection for a wide range of surfaces and components like hulls, propellers, shafts, rudders, sea chests, tanks, and keel coolers. These solutions contribute to maintaining the peak performance of the vessel while reducing the risk of cavitation on propellers and surfaces due to biofouling.

Commercial Shipping

In the commercial shipping industry, where efficiency and reliability are crucial, ultrasonic anti-fouling systems can play a vital role. These systems can help maintain optimal vessel speeds, reduce fuel consumption, and extend dry dock intervals by minimizing biofouling build-up. The non-toxic approach promoted by both Sonihull and Hull Shield makes them an environmentally friendly alternative in the shipping industry, which can contribute to sustainable practices and compliance with international regulations.

Sailing

For sailing enthusiasts, an ultrasonic anti-fouling system can help maintain the performance of their vessels while reducing the need for frequent hull cleanings or expensive antifouling paint applications. Among the various systems available, Sonihull and Hull Shield offer easy-to-install and low-maintenance anti-fouling solutions, ensuring that the sailing experience remains enjoyable and cost-effective.

Both Sonihull and Hull Shield also offer retrofitting options for existing vessels, making it easy for sailors to upgrade their current anti-fouling measures to more advanced and environmentally friendly solutions.

Environmental Impact and Sustainability

Environmental Considerations

When comparing ultrasonic anti-fouling systems like Sonihull and Hullshield, it's essential to consider their environmental impact. Both systems are designed to prevent biofouling on the hull by making it difficult for algae, barnacles, and other marine life to attach. Traditional antifouling systems often rely on biocidal coatings, which can release harmful microplastics and biocides into the environment. In contrast, ultrasonic systems like Sonihull offer effective protection against biofouling without the use of toxic chemicals or microplastics, significantly reducing their environmental footprint.

Ultrasonic antifouling systems also have the advantage of not disrupting the reproductive cycle or life patterns of marine organisms. This is a crucial consideration for maintaining marine biodiversity and the overall health of the ocean ecosystem.

Alternatives to Traditional Anti-Fouling Methods

Sonihull stands out as a particularly effective and eco-friendly alternative to traditional antifouling methods. It provides an efficient solution for hull protection that requires minimal maintenance. Sonihull systems can be installed on various surfaces exposed to raw seawater, such as hulls, shafts, propellers, waterjets, sea-chests, tanks, keel-coolers, box-coolers, pipework, intakes, and valves, making it a versatile choice for marine vessel owners and operators.

One of the primary benefits of ultrasonic antifouling systems is the potential for reduced fuel consumption. A clean hull can decrease a boat's fuel bill up to 30% since fouling on the hull leads to increased resistance and results in burning more fuel for every knot made.

Ultrasonic systems have been successfully integrated with other eco-friendly practices, such as hard hull coatings and high-speed usage. In Norway, the Green Marina Project achieved permanent antifouling by combining these techniques with Sonihull ECO systems.

In summary, Sonihull and Hullshield ultrasonic antifouling systems offer a more environmentally friendly and sustainable alternative to traditional antifouling methods. Out of the two systems, Sonihull stands out as a versatile choice for various marine vessels and structures. These systems substantially reduce the reliance on harmful biocidal coatings and contribute to a healthier marine environment.

Conclusion and Recommendations

When considering an ultrasonic antifouling system, it's crucial to weigh the pros and cons of the available options. Both Sonihull and Hull Shield are reputable manufacturers, each offering unique benefits to suit various needs and preferences.

Sonihull's ultrasonic antifouling systems boast environmentally friendly features that minimize the use of biocides and microplastics. Their easy installation process eliminates the need for drydocking or through-hull fittings, saving boat owners time and money.

On the other hand, Hull Shield offers powerful solutions such as the HD100, a four-transducer system designed for optimal efficiency and extended protection. Hull Shield's products can be used independently or in conjunction with other antifouling methods.

Understanding each system's testing and performance in real-world applications is essential. For instance, the Hull Shield ultrasonic antifouling system underwent BoatTEST's rigorous evaluations, demonstrating its efficacy in combatting fouling and reducing maintenance costs.

As cost-effectiveness is a significant concern, investing in an ultrasonic antifouling system can reduce expenses associated with haul-outs, hull cleaning, and bottom paint application. Moreover, the technology harnesses the power of sonar, emitting sound waves that inhibit biofouling growth without causing harm to marine life.

In conclusion, it is vital to conduct thorough research before selecting an ultrasonic antifouling system. Ultimately, the decision lies in the boat owner's hands, taking into account their specific needs and preferences, as well as considering the environmental impact, installation process, and overall effectiveness of the chosen technology.

Frequently Asked Questions

How do Sonihull and Hullshield compare in performance?

Both Sonihull and Hullshield use ultrasonic antifouling technology to prevent marine biofouling from settling on or inside vessels. However, specific performance details or comparisons between the two systems aren't available in the provided search results.

Which system is easier to install?

Both Sonihull and Hullshield systems are designed for easy installation. However, without specific installation details or comparisons available in the search results, it's difficult to determine which system is easier to install.

Are both systems suitable for all boat types?

Sonihull ultrasonic antifouling systems work on various types of materials used in boat construction and they provide protection for different boat designs. The information concerning Hullshield's compatibility with all boat types isn't available in the provided search results.

Which one has better customer reviews?

The specific comparison of customer reviews between Sonihull and Hullshield systems isn't available in the provided search results.

How do their prices compare?

A direct price comparison between Sonihull and Hullshield ultrasonic antifouling systems isn't available in the provided search results.

What is the life expectancy of each system?

The life expectancy information of Sonihull and Hullshield systems isn't provided in the search results.

Charlie is Editor-in-Chief of Sea Magazine