Boat Transom: Essential Guide for Maintenance and Repair

Boat transoms play a critical role in the overall structure and functionality of watercraft. As the vertical reinforcement at the rear of the boat, the transom strengthens the stern, and it's commonly the area where outboard motors are mounted. Transoms can be found on various types of boats, from small recreational vessels to larger offshore boats, and their design and construction can vary depending on the boat's purpose and requirements.

Understanding the importance of boat transoms is essential for boaters, as it can impact the vessel's performance, safety, and longevity. Transoms must be regularly inspected for signs of damage or wear, as they can face issues such as rot or cracks due to stress from motors. Choosing the right materials and construction methods for your boat's transom will ensure it remains durable and able to support the needs of your watercraft. Additionally, properly maintaining your boat's transom will safeguard its performance and reduce the risk of damage.

Key Takeaways

- Boat transoms strengthen and support the stern, often housing outboard motors

- Regular inspection and maintenance are crucial to prevent damage and maintain performance

- Choosing the appropriate materials and construction is essential for long-lasting durability and support

Understanding Boat Transoms

A transom is a crucial part of a boat's design and construction. It's the flat, vertical surface at the back of the boat that connects the two sides of the hull. This flat structure plays a significant role in reinforcing and supporting the back of the boat, as well as serving as a mounting point for the engine.

There are different types of boat transoms that cater to various needs and functions. One common type is the full transom, which spans the entire width of the boat's hull. This kind of transom is known for its stability and increased buoyancy, which helps resist stress from the engine and other operating forces.

A raked transom, on the other hand, features a slanting or inclined surface. This design provides a visually striking appearance and can improve water flow off the stern, potentially enhancing the boat's handling and performance.

Next is the reverse transom, which refers to a transom with an overhang that extends beyond the hull's bottom. This feature can offer additional buoyancy and protection against water splashing into the boat. The overhang on a reverse transom also increases surface area, which can improve performance and handling.

The cutaway transom is another type that allows for easy access to the water. This design involves a cut or opening at the bottom of the transom, which can make boarding or disembarking a boat much simpler. However, this design might not be suitable for boats that require significant engine support or those operating in rough water conditions.

Boat transoms can be made from various materials, with aluminum being a common choice due to its toughness and resistance to corrosion. Other materials include wood, fiberglass, and high-density composite materials, each offering distinct attributes that cater to a boater's preferences and requirements.

To maintain your boat's transom, regular inspections and appropriate care are essential. This involves checking for cracks, rot, or water leakage, which may compromise the transom's functionality and integrity. It's crucial to replace damaged transoms or seek professional advice when issues arise.

For more information on boat anatomy or related inquiries, please feel free to contact us. Our team of knowledgeable experts is always ready to assist with any questions or concerns.

Types of Boat Transoms

Boat transoms are an essential part of a vessel's structure, as they provide support and stability at the stern by connecting the two sides of the hull. There are several types of transoms to consider when examining different boats, each serving a unique purpose and providing different benefits.

A common type of boat transom is the full transom, which spans the entire width of the stern. This type of transom usually supports an outboard motor and offers excellent stability and strength for various boat sizes. Additionally, it provides ample surface area for mounting accessories, such as ladders and additional seating.

On the other hand, the reverse transom is characterized by an angled design, with the transom leaning forward from the waterline. This inclination adds an aesthetically pleasing touch to the boat's design, while also improving performance and reducing drag. Boats with reverse transoms are often seen in yacht racing, as the design enhances maneuverability and efficiency.

Cutaway transoms are a versatile option, featuring a notch or cut in the stern central part, allowing water to flow freely through it. This design is especially beneficial for shallow water boating and increases the ease of movement in and out of the water. Cutaway transoms also reduce stern lift, promoting stability and control during high-speed navigation.

Lastly, the canoe stern or double-ended design is found in boats that do not have a conventional transom. Instead, they feature a second stem piece resembling a canoe's bow. These boats originate from traditional canoe designs and offer advantages such as excellent tracking and stability in challenging water conditions.

Each type of boat transom has its unique applications and benefits, making them suitable for various boating needs and preferences. Understanding these structural differences can help potential boat owners make informed decisions when selecting the ideal vessel for their specific requirements.

Materials and Construction of Transoms

Transoms are an essential component of a boat's overall structure and stability. They come in various materials, each with its own construction methods and properties. The most common materials for transoms include wood, fiberglass, aluminum, and carbon fiber.

Wooden transoms have been used for centuries, providing a classic and traditional appeal to boats. However, they are more susceptible to rot and damage over time. To overcome these issues, fiberglass has become a popular alternative. Constructed by applying layers of fiberglass mat or cloth, they are bonded together using a specialized resin. This results in a strong, lightweight, and durable transom material that can resist water damage and other harsh marine conditions.

Aluminum and carbon fiber are also widely used materials for transoms on modern boats. Aluminum transoms are robust, lightweight, and corrosion-resistant. Carbon fiber, on the other hand, offers superior strength and stiffness without adding much weight to the boat's overall structure.

In the construction of transoms, bolts and hardware play a crucial role in ensuring durability and longevity. Stainless steel carriage bolts, washers, and lock-washers are typically used to secure the transom to the boat's stern. These fasteners provide a strong and stable connection that can withstand constant exposure to water, salt, and other environmental factors.

Modern boat builders are also exploring the use of composite materials for transom construction. These materials, often combining fiberglass, carbon fiber, Kevlar, and resins, create a composite transom that is strong, lightweight, and incredibly durable. They can withstand harsh marine conditions and offer a longer-lasting solution compared to traditional materials.

Each material and construction method has its own merits and drawbacks, making the choice of transom material largely dependent on the boat's intended use and desired performance characteristics. In summary, the materials commonly used in transom construction are evolving, with modern composites and advanced materials offering improved performance while preserving the essential functionality and integrity of the boat.

Boat Transom Issues and Potential Damage

Boat transoms are crucial structural components at the stern of a vessel, providing strength and serving various essential functions. However, they can face issues such as rot, damage, cracks, and corrosion, which can compromise a boat's safety and performance.

One of the most common problems with boat transoms is rot, specifically when they have wooden components exposed to constant moisture. Prolonged exposure to water can cause the wood to decay and weaken over time. The presence of rust or brown stains below screws or bolts is often a sign that water has infiltrated the transom, causing rot and damage.

Cracks in the transom can occur due to stress from the boat's engine, especially if the boat is frequently subjected to rough conditions or high speeds. Cracks may also develop around the sterndrive transom assembly, indicating an issue with the inner transom. Visible compression or cracks in these areas is a clear sign that boat transom problems need attention.

Corrosion can be another issue, particularly when boats are operating in saltwater environments. The combination of saltwater and metal components creates a conducive environment for corrosion, which can weaken the transom and its attachment points over time. Regular inspection and maintenance are necessary to prevent and address corrosion.

Boat transom issues should be addressed promptly to ensure the boat's safety and reliability. Ignoring the potential damage can lead to instability, difficulty in steering, and even structural failure in severe cases.

To determine whether a boat's transom is in good shape, one can perform a simple test by applying some pressure to the transom. If it feels soft or has visible signs of damage, it's crucial to seek professional assistance for repairs. Keeping the boat transom in optimal condition will ensure a safe and enjoyable boating experience.

Inspecting Boat Transoms

A thorough inspection of your boat's transom is crucial for maintaining its structural integrity and overall performance. The transom, the flat section that forms the square-shaped stern, is an essential component of the boat and is subjected to significant stress from the engine and water pressure.

Start the inspection by checking for any visible signs of damage or deterioration. Look for cracks in the gel coat, discoloration, or soft spots, particularly around the waterline and the area where the engine is mounted. These issues may indicate rot or structural weakness, and if left unattended, can lead to costly repairs or even catastrophic failure.

Next, ensure that the boat is properly supported on the trailer, with additional bracing if necessary, to minimize stress on the transom during the inspection. Inspect the motor mount bolts for signs of rust or corrosion, ensuring they are properly seated and snug. Pay special attention to the area around the engine mounting, as this is where the majority of the stress is placed on the transom.

Another critical aspect of the transom inspection is the area where the hull meets the transom. Inspect for any signs of delamination or separation, as these may indicate water intrusion or rotting wood on wooden transoms. If the boat is equipped with a transom-mounted drain plug, ensure it is in good condition and properly sealed to prevent water from entering the boat and causing damage.

In cases where you suspect rot or structural issues, it may be necessary to perform more invasive tests, such as drilling small holes into the transom to assess the extent of the problem. Consult a professional or reference a guide for proper techniques and steps for this process.

By regularly inspecting your boat's transom and addressing any issues early on, you can help maintain the overall safety, reliability, and performance of your vessel, ensuring many enjoyable seasons on the water.

Repairing and Reinforcing Boat Transoms

Boat transoms, especially for those with outboard motors, could face damage and wear over time. When it comes to maintaining the integrity and functionality of your boat, repairing and reinforcing the transom is essential.

To repair a damaged or rotted transom, you may need to remove the transom top and any associated fixtures. Then you will need to dig out the bad and rotted wood, let the interior dry, treat the area, and reassemble it according to the BoatLIFE guide. In some cases, an epoxy product like Git-Rot can help restore the wood if caught early enough.

Reinforcing a fiberglass boat transom involves following specific steps to ensure its durability and strength. After cleaning the fiberglass with denatured alcohol to remove contaminants, you'll need to perform tasks like patching holes, sealing joints, and grinding down uneven surfaces. Taking the necessary precautions as outlined in this guide is crucial to maintaining the structural integrity of your boat.

For aluminum boats, reinforcing the transom often means adding extra material to support the structure. You'll need to prepare the transom section, install the reinforcement, and attach any add-ons that provide extra stability. A comprehensive easy guide helps in understanding the key steps to enhance your boat's overall performance and longevity.

When replacing an old or damaged transom, it's essential to choose a suitable replacement that can handle the weight and stress of your boat's motor. Installing a transom saver can significantly reduce the stress on your boat's transom by distributing the motor's weight more evenly. In addition, using a strong bond, like epoxy or specialized adhesives, is crucial for securely attaching the transom to the boat's structure. This ensures a lasting repair and reduces the risk of future issues.

In conclusion, regularly inspecting, repairing, and reinforcing your boat's transom is vital for maintaining its structural integrity and ensuring a smooth and safe boating experience. Regular maintenance and the use of high-quality materials will go a long way in protecting your boat's transom from damage and preserving its longevity.

Boat Transoms with Different Vessels

Boat transoms come in various types and materials to cater to the unique requirements of different vessels. While some transoms provide structural support, others offer aesthetic advantages or functional benefits. Let's explore how boat transoms play a crucial role in different vessels, such as fishing boats, sailboats, and fiberglass boats.

Fishing boats often feature cutaway or reverse transoms for improved handling and aesthetics. These transoms are commonly seen on bay boats, where their design allows for better access to shallow waters while still maintaining ample stability.

On the other hand, sailboats sometimes use a canoe stern design with no transom. This double-ended design offers superior maneuverability and reduced water resistance, which is vital for optimal sailing performance. It's worth noting that not all sailboats have canoe sterns, as the choice would depend on factors such as size and sailing style.

Fiberglass boats frequently use flat transoms, whose main advantage lies in their stability and structural support. They are the most popular type of transom among traditional boats. Flat transoms provide a stable base for the engine as well as a space for mounting other accessories.

In some unique vessels like the proa, a type of multi-hull sailing craft, a transom may not always be present. These boats feature a narrow hull with asymmetrical ends, one for steering and the other for stability. However, the lack of a transom does not affect the overall functionality and seaworthiness of these boats.

From aluminum to wood, a boat's transom material is selected based on factors such as durability, weight, and resistance to corrosion. Aluminum, for instance, is tough and resistant to corrosion, making it a popular choice, especially for saltwater conditions.

Indeed, whether it's a fishing boat, sailboat, or any vessel in between, boat transoms serve an important role in a variety of watercraft. They provide structural support, enhance aesthetics, and help maintain seaworthiness, ensuring a safe and enjoyable boating experience for all.

The Role of Transom in Boat Performance

The boat transom is a crucial element in the overall performance and appearance of a vessel, as it serves as its backbone and provides essential support. The transom's primary role is to strengthen the boat's stern and aft sections, enhancing its stability and durability. A well-maintained transom is vital for the boat's structural integrity, as a damaged one can compromise the entire structure 1.

One of the significant functions of a transom is supporting the rudder, which plays a critical role in steering the boat. The transom's shape and angle can affect the rudder's effectiveness in maneuvering the vessel 2. The manner in which the transom is angled can also impact the boat's performance. A vertical transom is more common, but others may be raked, resulting in a slight overhang above the waterline, or designed as a reverse transom, where it angles forwards from the waterline 3.

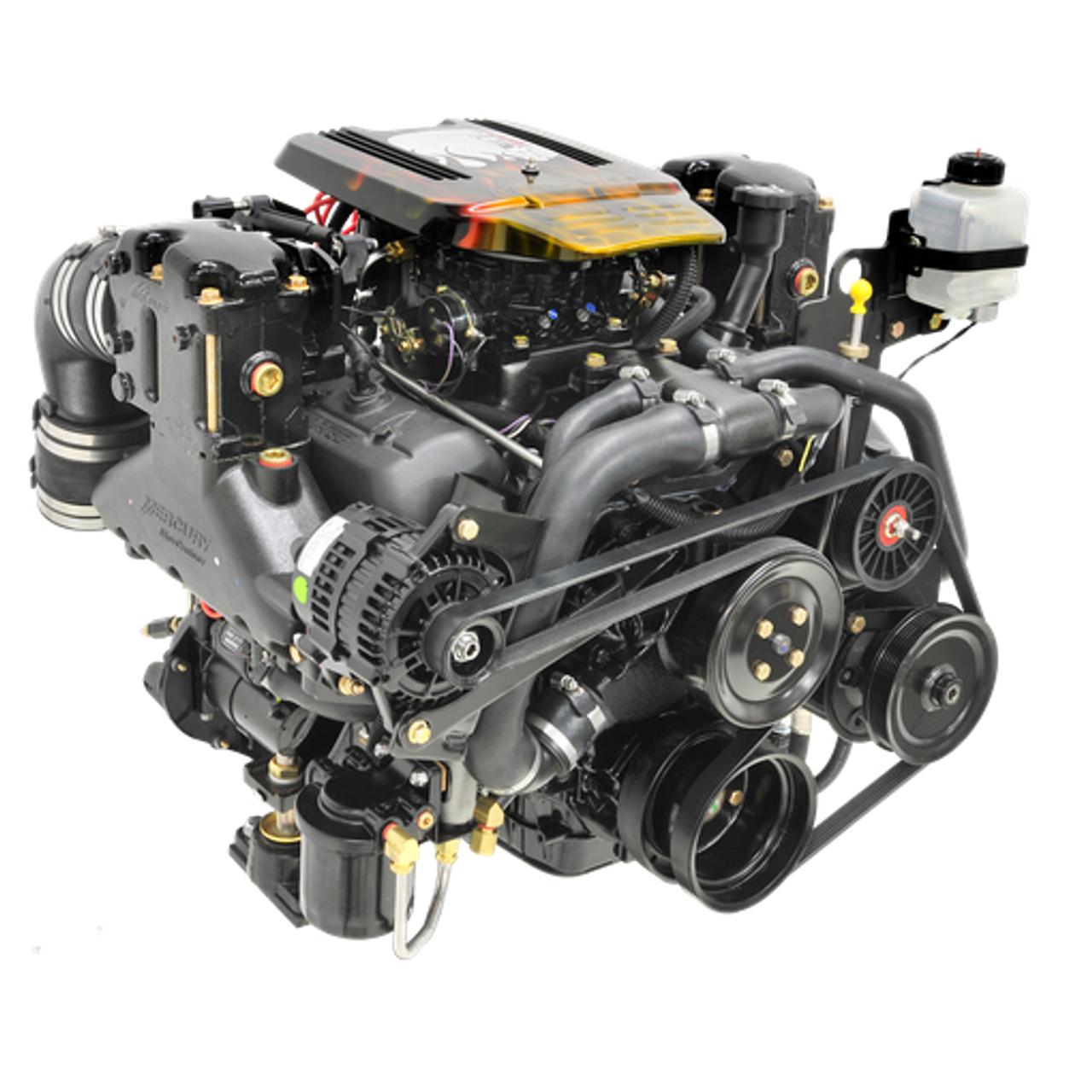

The transom's interface with the gunwale, or the upper edge of the boat's side, contributes to the boat's overall strength and serves as a point for attaching outboard motors, swim platforms, and other accessories 4. Outboards mounted on the transom provide propulsion for the vessel and can deliver efficient performance, depending on the transom's design and structure 5.

Finally, the transom can affect the boat's drag - the resistance a vessel experiences as it moves through water. A well-crafted transom contributes to reduced drag, which in turn leads to improved overall performance, fuel efficiency, and speed. The right transom angle, combined with a finely-tuned rudder and well-attached outboards, enables a boat to glide through water with less resistance, making the vessel more enjoyable and easier to navigate 6.

Transom Add-Ons and Accessories

Boat transoms can be enhanced with various add-ons and accessories to improve functionality and make your boating experience more enjoyable. Some popular additions include swim platforms, ladders, and setback brackets. Each of these components serves a unique purpose and can be customized to meet the needs of different types of boats.

Swim platforms are a great addition to your boat's transom, providing a stable and comfortable area for swimmers to relax, enter, and exit the water. They are usually made from materials like fiberglass or aluminum and can be custom-built to match the size and shape of your boat. Boat & Marine - Transom Accessories offers some high-quality options for you to choose from.

Ladders are essential for both safety and convenience on the water. Adding a ladder to your boat's transom enables easier access to the deck from the water or when boarding. Ladders come in various styles and sizes, including foldable and telescoping designs. Some even feature non-slip steps for added safety. It's important to choose a ladder that's compatible with your boat's design and your personal needs.

Setback brackets are another useful accessory for boat transoms. These brackets provide an extension for the outboard engine, allowing for better water flow and improved overall boat performance. The added distance between the engine and the transom can improve handling and stability, especially at high speeds. Installing a setback bracket is recommended for boats that require an adjustment in the space between the transom and the outboard engine.

In conclusion, boat transom add-ons and accessories like swim platforms, ladders, and setback brackets are valuable investments to enhance your boating experience. Each accessory serves a unique purpose, and you should consider them based on your specific needs and the type of boat you own.

Maintaining Your Boat's Transom

A well-maintained boat transom is essential for ensuring the safety and reliability of your boat. Regular inspection and proper care can prevent issues such as rot, structural damage, and water infiltration.

To start, conduct routine inspections of the transom for signs of damage, such as cracks, soft spots, or water stains. Also, check the hardware and fastenings connected to the transom, making sure they are secure and in good condition. If you suspect any damage or rot, drill small holes into the area to check the extent of the issue.

When working with an outboard motor connected to the transom, it's crucial to remove the transom top and any associated fixtures before assessing and repairing the damage. Ensure that all rotted wood is thoroughly removed and allow the interior to dry completely before treating the area and reassembling the components, as mentioned in BoatLIFE's blog.

It is also vital to keep an eye on the material used for your boat's transom, whether it is wood, fiberglass, or aluminum. Each material has specific maintenance requirements to ensure its longevity and structural stability.

Wooden transoms, in particular, require periodic checks for rot as outlined in BoatLIFE's article. If you have a fiberglass transom, inspect it for cracks or damaged gel coat surfaces. Aluminum transoms may require reinforcement or additional protection against corrosion, as described in this Aluminum Boat Transom Reinforcement tutorial.

In conclusion, maintaining your boat's transom is an integral aspect of boat maintenance. Regular inspections, timely repairs, and proper care for different materials will ensure your boat remains safe, reliable, and in top condition.

Frequently Asked Questions

What is the purpose of a boat transom?

A boat transom is the flat, vertical surface at the back of a boat that connects the two sides of the hull. It plays an essential role in providing structural support and reinforcement to the boat. Furthermore, the transom serves as a mounting platform for outboard motors and other accessories like swim platforms and ladders.

How is a boat transom repaired?

To repair a boat transom, first inspect it for any soft spots or discoloration indicating rot. If rot is suspected, drill small holes into the area to check the extent of the damage. Then, depending on the severity of the rot, the rotten parts should be removed, and the cavity filled with a suitable material like marine-grade plywood or high-density foam. Finally, fiberglass is applied, and the surface is sealed and painted.

What are the typical costs for boat transom repair?

Boat transom repair costs can vary depending on the severity of the damage, the material used for the repair, and labor costs. The price range can be anywhere from a few hundred dollars for small and straightforward repairs to several thousand dollars for complex repairs on larger boats. It is recommended to get multiple quotes from marine repair professionals to get an accurate estimate for the specific repair needed.

How does a transom saver protect a boat?

A transom saver is a simple device used to protect a boat's transom when towing it on a trailer. It acts as a support between the boat's transom and the trailer, absorbing shock and vibration from the road, reducing stress on the boat's transom. This way, it helps in preventing damage to the boat, especially when traveling long distances.

What are the key features of a pontoon boat transom?

A pontoon boat transom shares the structural reinforcement and mounting platform features with other types of boat transoms. However, pontoon boat transoms are specifically designed for pontoons, which have buoyant tubes on either side of the boat instead of a typical hull. These transoms usually have a more substantial cross-section and are reinforced to accommodate the extra weight and forces associated with pontoon boats.

What is the difference between a transom on a sailboat and a jon boat?

While both sailboats and jon boats have transoms that provide structural support and reinforcement, there are notable differences in their design. The transom in a sailboat is often more angled or rounded, mainly designed to accommodate the boat's shape and to make it more hydrodynamic. In contrast, jon boats have a flat, squared-off transom, which focuses on providing a stable platform and enabling easy attachment of outboard motors. Additionally, sailboat transoms may have openings for rudder and tiller attachments, while jon boat transoms do not.

Footnotes

- https://workshopinsider.com/boat-transom/ ↩

- https://en.wikipedia.org/wiki/Transom_(nautical) ↩

- https://the-bosun.com/boat-transom-a-comprehensive-guide/ ↩

- https://maritimepage.com/what-is-a-transom-on-a-boat-a-beginners-guide/ ↩

- https://www.wikihow.com/What-Is-a-Transom-on-a-Boat ↩

- https://the-bosun.com/boat-transom-a-comprehensive-guide/ ↩

Charlie is Editor-in-Chief of Sea Magazine