Bilge Pump - Boaters Need to Know: Essential Tips for Optimal Performance

Bilge pumps play a crucial role in keeping boats safe and afloat by removing excess water from the bilge, the lowest part of a boat's hull. Boaters must understand the importance of their bilge pump system and how to maintain it properly, as failure to do so could lead to serious consequences. A well-functioning bilge pump not only prevents the boat from taking on too much water but also contributes to a cleaner boating experience by preventing the discharge of oily bilge water.

There are various types of bilge pumps available, each with its own set of features and benefits. When selecting the right bilge pump for their vessel, boaters must consider the boat’s size, hull type, and the environmental conditions they plan to encounter. Along with choosing the right pump, proper installation and regular maintenance are essential for the pump to perform efficiently. Moreover, it's important for boaters to familiarize themselves with the legal and safety considerations surrounding bilge pumps, as there may be specific regulations to follow in their location.

Key Takeaways

- Bilge pumps are essential for boat safety and preventing water accumulation.

- Choosing the right bilge pump involves considering boat size, type, and environment.

- Proper installation, maintenance, and adherence to legal guidelines ensure effective bilge pump performance.

Basics of Bilge Pumps

What is a Bilge Pump

A bilge pump is an essential safety device for boaters, as it helps remove water that accumulates in the bilge, the lowest part of a boat's hull, which collects water from leaks, condensation, and other sources. The pump's main purpose is to maintain the boat's stability and prevent it from sinking due to excessive water in the bilge.

Need for a Bilge Pump in Boats

Bilge pumps are critical for ensuring the safety of both the boat and its passengers. When water accumulates in the bilge, it can lead to various problems, such as the boat losing buoyancy, reduced maneuverability, and increased risk of capsizing. By regularly pumping out the bilge water, boaters can maintain a safe and stable environment on their vessel.

It is also essential for boaters to be aware of proper bilge pump usage to minimize environmental impacts. For instance, boaters should avoid pumping bilge water that is oily or contains pollutants.

Types of Bilge Pumps

There are two main types of bilge pumps used on boats:

- Manual Bilge Pumps: These pumps require manual effort to pump the bilge water out of the boat. They are typically operated using a lever or handle and are more suitable for smaller boats or as a backup pump on larger vessels.

- Electric Bilge Pumps: Electric pumps automatically remove water from the bilge area when a float switch activates them. They are powered by the boat's battery and are more common on larger boats due to their efficiency and the ability to handle higher volumes of water.

When selecting a bilge pump, boaters should consider factors such as the size of their boat, the typical water volume in the bilge, and their personal preferences. It is also recommended to have a secondary pump as a backup in case the primary pump fails.

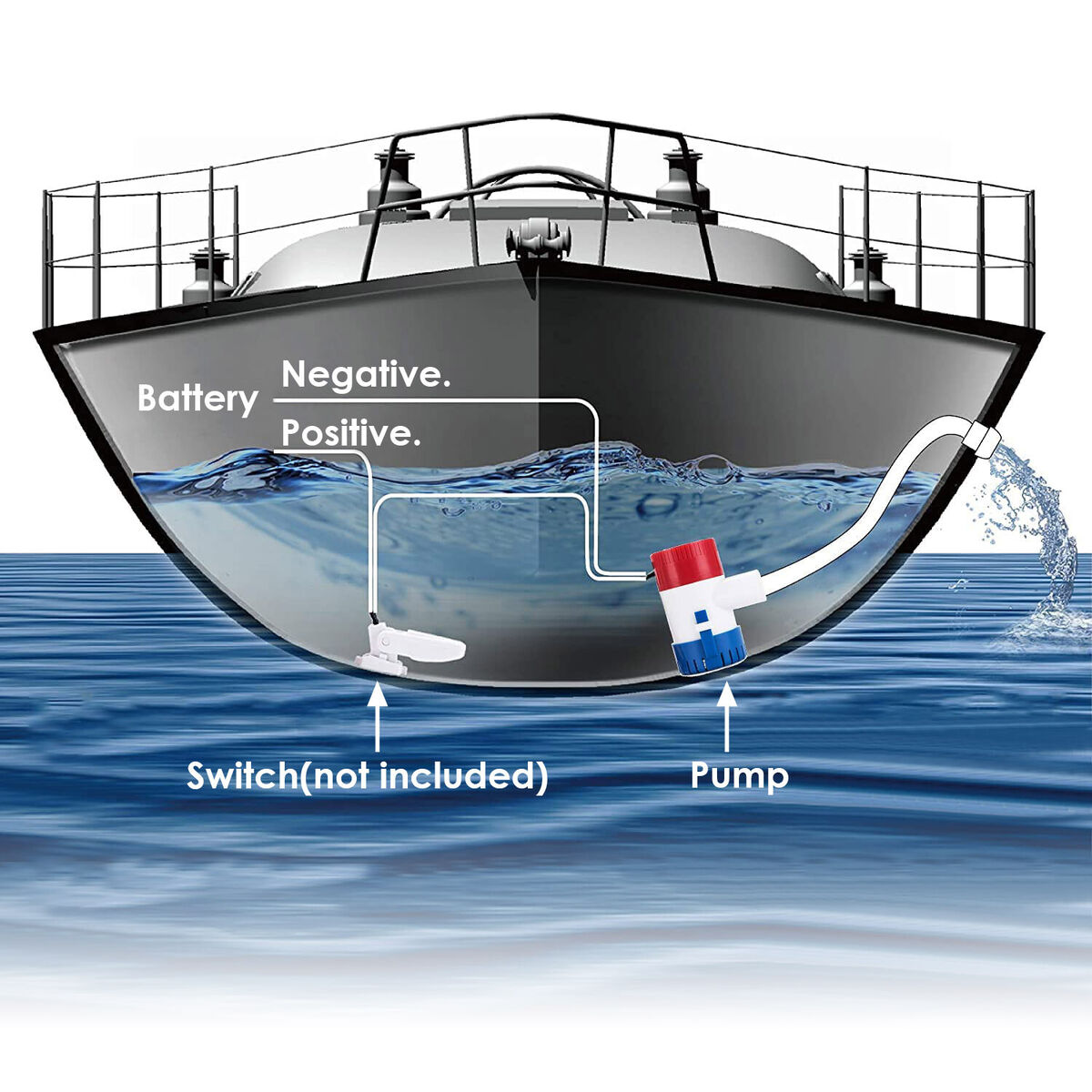

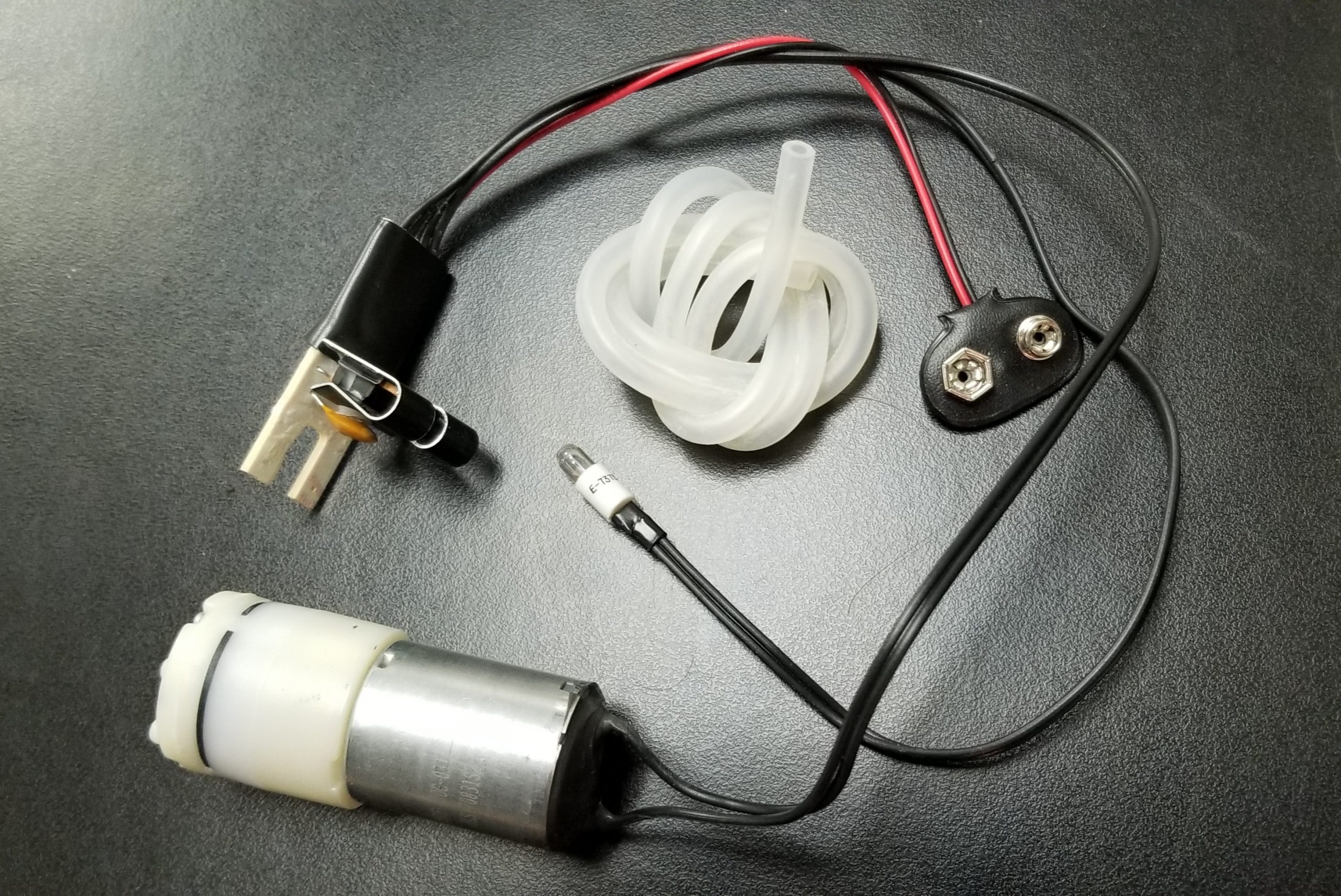

Understanding Bilge Pump Components

Bilge pumps are essential for keeping a boat safe from water accumulation in the bilge area. In this section, we will discuss the main components of a bilge pump: the float switch, impeller and diaphragm, hose, and wiring.

The Float Switch

The float switch is a key component of an automatic bilge pump system. It is responsible for detecting the water level in the bilge area and activating the pump when necessary. The float switch typically consists of a floating element connected to a mechanical or electrical switch. As the water level rises, the floating element lifts, triggering the switch to activate the pump. It is crucial to ensure that the float switch is installed correctly and functioning properly for optimal performance and safety.

Impeller and Diaphragm

There are two main types of bilge pumps: impeller pumps and diaphragm pumps. Impeller pumps use a spinning impeller to move the water, while diaphragm pumps utilize a flexible diaphragm to create suction.

Impeller pumps are generally self-priming, meaning that they can begin pumping without being filled with water first. However, they may become less effective if debris or other particles enter the impeller. On the other hand, diaphragm pumps are less susceptible to damage from debris but may require manual priming before use.

Hose and Wiring

The hose and wiring are critical components of a bilge pump system. The hose is responsible for channeling water away from the bilge area and overboard. It is essential to ensure that the hose is free from leaks, kinks, and blockages for optimal performance.

Wiring plays a crucial role in connecting the bilge pump to the power source and ensuring it functions reliably. Proper wiring involves using the appropriate wire size, conforming to marine standards, and ensuring connectors are watertight to prevent corrosion or short circuits.

By understanding the components of a bilge pump, boaters can better maintain their system and ensure their safety on the water.

How to Select a Suitable Bilge Pump

Flow Rate

A crucial factor to consider when choosing a bilge pump is its flow rate, which is typically measured in gallons per hour (GPH). The flow rate determines how quickly the pump can remove water from the bilge. It's essential to choose a pump with a high enough flow rate to effectively handle your boat's size and potential water flow. To determine an ideal flow rate for your boat, consider factors like the volume of water that your boat can take on and how quickly it needs to be removed.

Suction and Capacity

The suction capacity of a bilge pump indicates how effectively it can remove water from the lower parts of your boat. Centrifugal bilge pumps are commonly used, as they can handle small debris and have good suction abilities. Pumping capacity refers to the amount of water a bilge pump can move within a specific timeframe. When it comes to suction and capacity, ensure to select a pump that matches your boat's requirements and can effectively remove water from the bilge.

Pump Size and Type

The physical size and type of the bilge pump you choose are essential factors, as your boat may have limited space to accommodate the pump. There are different types of pumps available, like centrifugal pumps and diaphragm pumps. Centrifugal pumps are efficient in handling small debris and are often more compact, making them a common choice for boaters with limited space. On the other hand, diaphragm pumps are more suitable for larger boats with a higher volume of water, as they can pump water uphill and handle larger debris. Consider the available space in your boat and the type of pump that will work best for your needs.

Manual Vs. Automatic Bilge Pumps

When selecting a bilge pump, you will also need to decide between manual and automatic bilge pumps. Manual bilge pumps require manual activation and are ideal for smaller boats or as a backup system. They provide more control over when the pump operates, but they may not be as efficient as automatic bilge pumps. Automatic bilge pumps activate when they sense water, ensuring constant protection for your boat even when you're not present. However, they may also have a higher power consumption. Balancing your needs for control, efficiency, and power consumption will help you determine which type of bilge pump is best for your boat.

Bilge Pump Installation Process

Placing the Pump

When installing a bilge pump, it's crucial to choose the right location inside the boat's hull. The pump should be placed in the lowest part of the bilge to efficiently remove water. Make sure it is not obstructed by any debris, such as pebbles or leaves, that may affect its performance. To prevent airlock, position the centrifugal bilge pump so that the intake is entirely submerged when the boat is in a still wave state.

Fittings and Connections

Once the pump is securely placed, it's time to connect it to the plumbing system. Start by installing a strainer on the intake, which will help prevent debris from entering the pump and causing it to jam. Next, connect the pump's discharge port to the appropriate thru-hull fittings using hoses or pipes, ensuring a tight seal to prevent leaks.

Here's a brief overview of the process:

- Install a strainer on the pump's intake

- Connect the discharge port to the thru-hull fittings

- Use hoses or pipes with proper diameter and pressure ratings

- Secure the connections using clamps or fittings specified by the manufacturer

Electrical Requirements

Proper wiring and electrical connections are crucial for the bilge pump's safe and efficient operation. Ensure that the voltage provided by the boat's electrical system matches the pump's requirements. Follow these steps for a successful installation:

- Use marine-grade, tinned wire with the right gauge specified by the pump manufacturer

- Connect the pump's positive lead to a fuse or circuit breaker to protect against electrical shorts

- Wire the pump to a float switch or a dedicated switch panel for manual operation

- In case of emergency pumps, consider wiring them to a separate battery source, providing backup power during electrical failures

- Secure all electrical connections using heat shrink connectors or terminals, which helps prevent corrosion and ensure longevity

By following these guidelines, boat owners can efficiently install their bilge pumps, enhancing safety and reliability on the water.

Bilge Pump Maintenance and Cleaning

Routine Checks

Boaters should perform routine maintenance on their bilge pumps to ensure proper functioning and longevity. This includes:

- Regularly inspecting the bilge pump and float switch for any visible signs of damage or wear

- Checking for debris or obstructions in the pump's intake and discharge hoses

- Testing the pump's operation by manually activating the float switch

- Assessing the battery's charge to be certain it can provide enough power to operate the pump

Cleaning the Bilge Area

Proper cleaning is essential for maintaining the optimal performance of a bilge pump. Boaters can follow these steps to clean the bilge area:

- Turn off the power to the bilge pump to prevent it from accidentally activating during cleaning

- Remove any visible debris or sludge from the bilge to prevent blockages

- Use a mild, eco-friendly cleaning solution to wash down the bilge area

- If the bilge has oil residue, consider using oil absorbent material or steam cleaning services to remove the oil

- Allow the bilge to dry before reactivating the power to the bilge pump

Handling Damages and Replacements

If boaters notice any damage or wear during their routine maintenance, they should consider the following:

- Replace damaged hoses to maintain proper water flow and prevent leaks

- Consult the pump's manufacturer for recommended repair or replacement parts

- If the pump requires more than a simple repair, consider acquiring a new modular bilge pump to minimize downtime and keep the bilge area clean

- Follow manufacturers' guides and tutorials for step-by-step instructions on replacing damaged components or installing a new bilge pump

By regularly performing routine checks, cleaning the bilge area, and handling damages and replacements as needed, boaters can ensure the longevity of their bilge pump and maintain a clean, functioning bilge area in their vessel.

Potential Risks and Troubleshooting

Sinking and Flooding

Bilge pumps play a crucial role in preventing boats from sinking by removing accumulated water from the bilge area. However, they can become overwhelmed if the water intake rate exceeds the pump's capacity. Boaters should regularly inspect their bilge pumps for proper operation and address any potential issues promptly. In case of emergencies, having a backup bilge pump or a manual pump can be helpful in mitigating the risk of sinking or flooding.

Debris and Leak Issues

Leaks or debris accumulation in the bilge area can lead to pump malfunction. If foreign materials such as leaves, plastic, or other debris clog the pump, its efficiency decreases, resulting in poor performance. To minimize the risk of debris-related issues, it is recommended that boaters clean the bilge area regularly and inspect the pump's intake strainer. Further, to identify and address any leaks, boaters should monitor the bilge water levels and take necessary action if a steady increase in water level is observed.

Electrical Problems

Bilge pumps rely on electrical systems to function, and any issues in the wiring, battery, or connections can lead to malfunctions. Boaters should ensure that the electrical components of the bilge pump are in optimal condition and corrosion-free. Regularly inspecting and maintaining the battery, wiring, and connections can help reduce the risk of electrical problems. Additionally, installing a high water alarm can alert the boater about potential issues, allowing them to take timely action to prevent severe damage to the vessel.

Dealing with Bilge Pumps in Special Circumstances

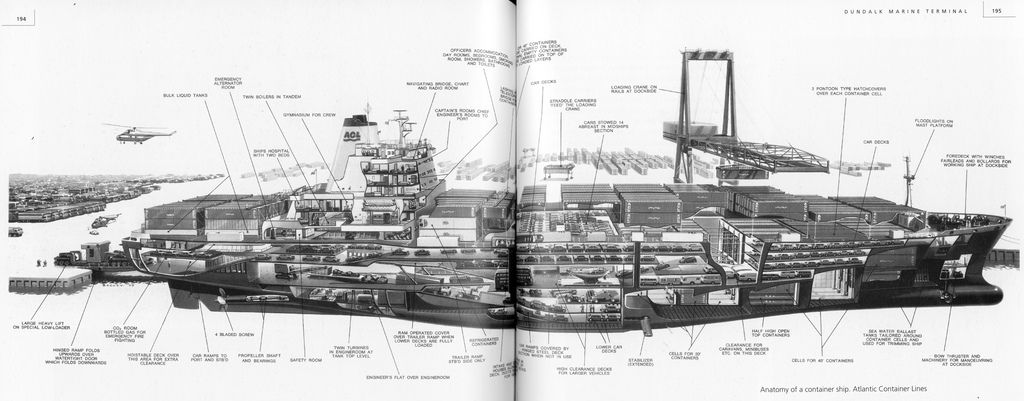

Bilge pumps play a crucial part in maintaining the safety of boaters, regardless of the type of vessel they operate. This section will compare the use of bilge pumps in larger vessels vs. smaller boats, as well as the differences between powerboats and sailboats.

Pumps for Larger Vessels Vs. Smaller Boats

In general, larger vessels require more powerful bilge pump systems in comparison to smaller boats. Larger vessels have greater bilge capacities and water accumulation, which calls for stronger, more capable pumps. On the other hand, smaller boats usually have less bilge capacity, making it easier for bilge water to rise rapidly and require the need for higher-capacity pumps1. Therefore, selecting the correct type of bilge pump for your vessel's size is crucial to ensure optimal boat maintenance and safety.

Common types of bilge pumps used in different vessel sizes include:

- Float switches: These devices trigger the pump when bilge water reaches a certain level. Float switches are widely used in both large and small vessels due to their efficient and reliable operation2.

- Piston pumps: These high-capacity pumps are preferred in larger vessels, thanks to their ability to handle higher volumes of water at faster speeds.

Powerboats and Sailboats

Powerboats and sailboats have different bilge pump requirements due to their unique designs and uses. Powerboats generally have more space in their engine compartments, making it easier to implement a larger and more powerful bilge pump system. Moreover, powerboats usually generate more noise, so the noise created by bilge pumps can be less of an issue compared to that on a sailboat.

Sailboats, on the other hand, often have less space in their bilge compartments; hence, require more compact and efficient bilge pumps. Additionally, sailboats tend to operate more quietly, requiring a bilge pump system with minimal noise disturbance.

In conclusion, understanding the unique bilge pump requirements for different types of vessels is crucial in selecting the right size and type of pump. Boat maintenance requires a balance between safety and efficiency, with the pump being an essential component in ensuring that the bilge water is managed appropriately under various circumstances.

Footnotes

Legal and Safety Considerations

Boat Owners' Responsibility

Boat owners have the responsibility to maintain a functional bilge pump system on their vessels. This system is crucial for preventing excess water from accumulating in the boat's bilge, which could lead to capsizing or other dangerous situations. Proper maintenance of the bilge system includes periodically checking for wear, debris, and ensuring the battery is in good working condition. Additionally, boat owners should evaluate their bilge pump's flow rate and motor to verify it can effectively remove water from their vessels 1.

Key Regulations

There are specific regulations concerning bilge pumps and boat safety. For example, boats with a certain capacity or length may be required to have a specific flow rate for their bilge pumps, according to boating laws 2. Diaphragm bilge pumps or other types of boat bilge pumps must be installed following these regulations.

Moreover, boat owners may also be required to have an emergency switch or breaker connected to their bilge system, ensuring that the pump can be deactivated in case of malfunction. It is vital to familiarize yourself with these regulations and requirements to ensure your boat is compliant with the law and safe to operate.

Safe Usage Tips

Alongside legal responsibilities, boat owners should follow safe usage practices for their bilge pump systems. Here are some recommendations:

- Regularly inspect the bilge pump, motor, and related components for wear or damage.

- Avoid overloading the bilge pump with debris or contaminants by using filters or absorbent socks 3.

- Ensure the battery is charged and working correctly, as it powers the bilge pump.

- Install a float switch to automatically activate the bilge pump when water reaches a certain level in the bilge.

- Keep the boat's stern, where the bilge pump outlet is usually located, clear of obstructions to ensure efficient water flow.

By following these guidelines and keeping up with legal requirements, boat owners will contribute to safer boating practices and a more enjoyable experience on the water.

Frequently Asked Questions

How to install a bilge pump?

Before installing a bilge pump, ensure that you have the necessary tools and equipment. Start by selecting a location for the pump in the lowest part of the bilge, where water can accumulate. Mount the pump with fasteners and ensure proper wiring connections. Make sure to route the discharge hose above the waterline to prevent backflow. For detailed instructions, refer to the manufacturer's guidelines.

What size bilge pump is needed for my boat?

To determine the appropriate bilge pump size for your boat, consider factors such as boat size, bilge compartment depth, and potential water ingress. A common rule of thumb is to have a bilge pump with a flow rate of approximately 2000 GPH (gallons per hour) for every 30-40 feet of boat length. However, specific requirements may vary depending on individual boat design and usage.

What are the different types of bilge pumps?

There are three main types of bilge pumps: manual, electric, and engine-driven. Manual bilge pumps require physical effort to operate and are typically used in small boats. Electric bilge pumps are the most common and are either submersible or remote-mounted, with various flow rates and voltage options. Lastly, engine-driven bilge pumps are high-capacity pumps suitable for larger vessels experiencing significant water ingress.

How does a bilge pump float switch work?

A bilge pump float switch is a device that activates the bilge pump when the water level in the bilge reaches a certain height. Typically, a float switch is mounted in the bilge compartment. As the water level rises, the buoyant float switch is lifted, activating the bilge pump. Once the water level drops, the float switch disengages, turning off the bilge pump.

Should I leave the bilge pump on while boating?

It is generally advisable to leave the bilge pump on while boating, especially when the boat is unattended or when there is a chance of water ingress. However, it is important to monitor the bilge pump's operation and check for potential issues such as excessive water ingress or pump malfunction.

When is a bilge pump not required?

Bilge pumps are not required for some small boats, such as canoes, kayaks, or rowboats, where any water ingress can be easily managed manually. It is essential, however, that boaters are familiar with their vessels' requirements and ensure adequate safety measures are in place.

Charlie is Editor-in-Chief of Sea Magazine